updated 2021

A pottery firing changes the plastic clay body irreversibly into a hard ceramic body. Bisque fires to about 950 -1000° C. It still has some porosity and so will absorb water. Over 1000° C the body will start to become vitrified, glassy, and impervious to water. Usually for ease of handling the pottery there are two firings, first the bisque, also called biscuit, and then after the pots have been glazed, the glost or glaze firing. To change the plastic clay pots, greenware, into a bisque, heat is applied by electricity or by burning a fuel such as gas. The rate of temperature rise is modified by the ability of the clay to withstand the increase of temperature. And also by the need for the clay to be properly developed at the molecular level to provide structural strength, resistance to wear, and hygienic use.

To achieve this you need to be aware of the progress of the firing, taking in to account the following;

- What kiln firing is It? Is it Earthenware, Mid-fire, or Stoneware and Porcelain?

- Are there some glazes which perform better at the bottom, at the top, and so on?

- How much pottery, volume of material, is in the kiln. That is, the density of the packing. Generally kilns work better with a light packing at the bottom. For reduction firings pack very closely.

- Are there firing cones set and are they visible through the port?

- What is the condition of the kiln and its capacity to reach temperature in good time. Older kilns with old electric elements take longer.

- The amount of available time. There may be set time limits for the use of the kiln, due to a buildings opening hours, community restrictions, or fire regulations.

- The fuel and resources available. You don’t want to run out of gas.

- Do you know how to operate the various instruments and apparatus, as well as adjusting the burners and flues, to fine tune the firing, for reduction, or not for reduction, and for temperature?

- Your timetable. A kiln can not be left unattended nor can the responsibility be casually undefined leaving no one in attendance. Any other commitments need to be reorganized.

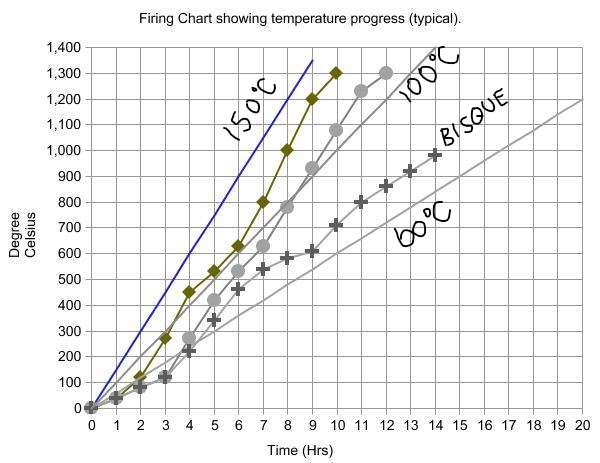

Roughly we can say the Bisque firing is 60°C per hour up to about 1000°C. The Glost firing is 60°C per hour until past 100°C, and then 100-150°C per hour.

Generally the firing procedure is straight forward. Increase the fuel via the burner, or turn up the electric controllers. A digital kiln controller can automatically fire an electric kiln and is now very common. But the settings in the controller need to reflect these same considerations. The overall purpose is to give the clay and glaze a strong, beautiful finish. A fast rate of increase, a quick firing, is possible, but this leads to many problems, such as cracking of the ware, glaze imperfections, and poor body strength which shortens the life of the ceramic. So we need to consider the reasons for adjusting the various controls and why a controlled temperature rise is necessary.

Think of a lump of clay. The heat has to penetrate deep within the lump evenly through to the center. During this time the changes to the clay have been taking place gradually from the outside in. The release of water and other combustion gases, the burning out of carbonaceous matter, is not complete unless the heat is given time to penetrate right into the clay. At the same time the heat is making molecular changes to the clay. Too much heat too fast and surface molecular changes will take place, sealing the outside, before any expulsions have had time to get out, and trapping volatile materials inside. Such an uneven and impure body is structurally weak.

This is all from a technical standpoint. There is much about ceramics which has a beauty, a liveliness, perhaps achieved pragmatically, not knowing or applying anything about all this. But to avoid, cracks, crazing, underdeveloped glazes, glazes running onto shelves, clay over-fired and brittle, or poorly fired clay with weak ceramics, there are fundamentals worth knowing.

The major points of transition are;

- 100° C. Water boils and turns into steam.

- 200° C. Vegetable matter, such as grass and paper, combust into smoke.

- 300-500° C. Chemically combined water is released.

- 573° C. Quartz inversion in both heating and cooling. The molecular changes in the clay will take the heat energy and there will be less of a temperature increase. Between 500-600°C, don’t panic and think you need to turn up the kiln. After the quartz inversion, the firing naturally returns to temperature increase. By wrongly turning up the firing, the changes will be interrupted.

- 700-800° C. Carbon and sulphur are burnt off and a strong smell is evident.

- 900° C. Clay begins to vitrify.

- For Reduction firing, begin reduction. Strong reduction evident by flickering orange/red flame.

- 1000° C. Bisque firing end point.

- For Glost firing continue. The maturity of the clay and glaze is what determines the end point. For example, Earthenware might be 1100° C, Midfire 1180° C, Stoneware 1260° C, and Porcelain 1300° C.

- 1100-1300° C. Variable reduction, light/medium, depending on time table.

At the end of the firing it is recommended there is a soak, or a hold of temperature but there are variations to what this means..

- Soak or Hold; For each level of maturity there is a similar range of about 50°C to soak .

- It can be taken to mean, stay at the top temperature for a period of time, but this means the heat work is increasing, over the top temperature. #Note. Do not start a Hold or Soak at the mature temperature or when the cone is down, because the continued heat work will be an overfire.

- Another way is start before reaching top temperature. For example, from 1200 and slowly reach top temperature at 1250° C.

- Or, after reaching top temperature, immediately turn off and drop down, for example, 1250 down to 1200° C. and hold or slowly increase back to top temperature

- At end of firing close all exit ports and flues. Turn off electrics or gas supply.

- Another possibility: Cooling down – 1100-1000° C. Oxidising soak in the cooling cycle to improve glazes.

- Cooling down – 250-200° C. Crystabolite inversion on cooling. Do not open kiln door or vents.

- Under 200° C , you can open kiln very slightly to hasten cooling.

- Don’t unload until after not hot to touch.

The ordinary impulse in a kiln firing is to clamp the kiln, that is to block all the exits and outlets such as the holes in the top of an electric kiln, or the flue in a gas kiln. The idea I suppose is to keep the heat in the kiln. In the early stages of the kiln firing this is a mistake. As the kiln heats up it is giving off steam and is burning off materials, producing smoke and other gases. These gases have to be vented otherwise they will affect the clay and glazes. Perhaps most importantly is when sulphur is burnt off starting at about 700°C it mixes with water vapour to produce sulphuric acid and this attacks the metals. You can see the corrosion around the doors on many older kilns. This is completely unnecessary. Leave the ports open until above 800°C, or more.

Although 1300° C is mostly given to be the ideal high temperature firing, the preference for firing to 1300° C is not really a standard, and in a lot of places it is 1250° C. It is said this preference arose from the historical search many centuries ago in Europe looking for the secret of Chinese Porcelain. The required high temperatures were unknown at that time in Europe and it was a quest to develop the skills and kilns to get higher and higher temperatures. Today this quest is pointless, and clay and glazes are easily developed to mature at 1250° C, saving time, effort and energy. There are also clays and glazes which mature at lower temperatures, and while not the equivalent of say, porcelain, they are suitable for making functional pottery.

Stages in setting manual switch temperature increase. You can also set this for electronic operation.

1. 0-100°C :Top vent open. Low setting on dial.

2. Do not exceed 60°C per hour. This allows moisture to be carefully driven off before it would erupt as steam.

3. 100-500°C: For bisque continue at 60-80°C per hour. For Glost firing continue at about 150°C per hour. Watch pyrometer readings to gauge how much to turn up, or down.

4. 500-600°C : The temperature increase naturally drops as there is a Quartz Inversion taking place. A crystalline change within the molecular structure. Do not turn up. Wait. Let the slow down take place.

5. 600-700°C : The rate of increase should return to normal after 600°C, but may need turning up a bit. For bisque continue at 60-80°C per hour. For Glost firing continue at about 150°C per hour.

6. 700-800°C : Sulphur is driven off. There is a noticeable smell. Make sure the vents are still open otherwise the sulphur will combine with water vapour to form sulphuric acid and corrode the kiln. Do not go too fast.

7. 1000°C : End of Bisque.

8. Glost Firing : Continue observing pyrometer and maintain rate of increase depending on kiln, with top vent open. Check once an hour or more, turning up half a notch, and checking again. Towards the end you will need to watch cones. The temperature and the heat work are different and the cones may be bending. Follow instructions above for end of firing. Close top vent.

9. Let cool till under 100°C.

Straight lines are representing various rates of increase. The middle one is set at 100°C per hour. The one below is set at 60°C per hour. The top one is too fast at first, but is set at 150°C per hour. Then the others are typical results when adjusting for critical points. Note they all go slow to start.

(Right click on image to open, save or download.)

Using a manual kiln regulator switch.

Turn on the kiln by going to low, and then after a while, check the pyrometer. Now log the temperature and the time. Do this every hour. What you are reading is the temperature increase per hour. Then according to the rate of increase, if it is too much turn the dial down by 1/2, if too slow turn it up 1/2. Gradually you will see what this is doing and can find what each increment is doing and make the appropriate change.

At higher temperatures, a temperature increase requires more energy and you will have to also take this into account. But the adjustments will be obvious from the logs you have been taking, that is, what the temperature reads at regular intervals and the incremental increase.

What you have to take into account is what is a good rate of increase at any particular time in the firing, with an understanding of the technical changes taking place. This can be read in the other notes.